C7027A1064 Honeywell Minipeeper UV Flame Sensor

$410.00

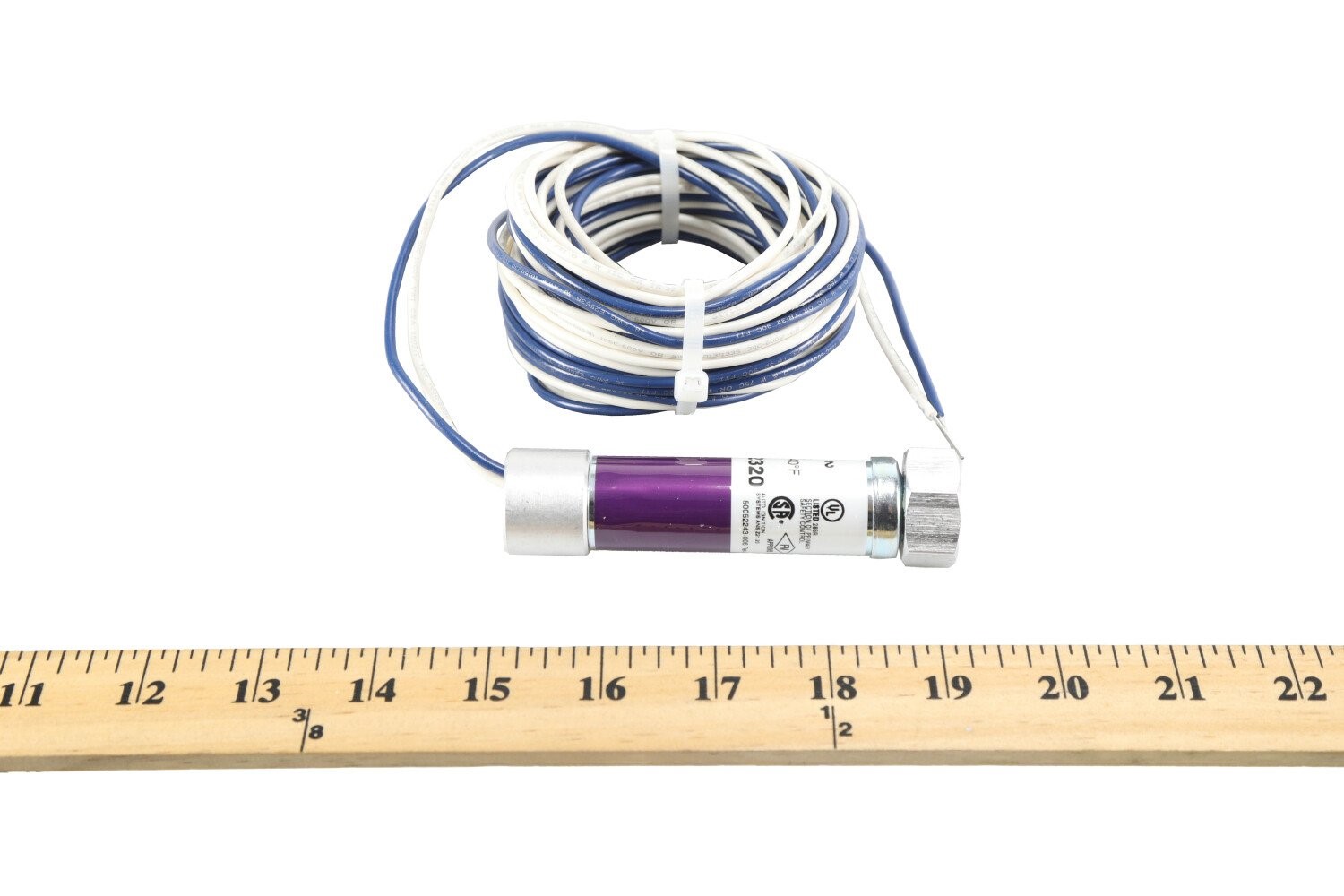

The Honeywell C7027A1064 Flame Sensor -40 TO 215F 1/2 IN CONDUIT SPUD. 24 FT. LEADS.

5 in stock (can be backordered)

The Honeywell C7027A1064 Flame Sensor -40 TO 215F 1/2 IN CONDUIT SPUD. 24 FT. LEADS.;Minipeeper Ultraviolet Flame Detector, Used for Coal, Gas and Oil Fired Burners, 288 Inch Lead Length, -40/215 Degree Ambient Temperature, Mounts on 1/2 Inch Sighting Pipe Using A Integral Collar, Includes 1/2 Inch NPT Spud Connector

Overview

The Honeywell C7027A1064 is a Minipeeper ultraviolet (UV) flame sensor used in burner control systems. It senses the UV emissions from a flame to confirm presence, and is suited for installation in tight locations thanks to its compact design and standard ½-inch mounting. It often includes a 24 V LED status indicator for visual confirmation of flame status.

Specifications

| Specification | Detail |

|---|---|

| Model | C7027A1064 |

| Sensor Type | Ultraviolet (UV) flame detector |

| Operating Temperature | ~0 °F to 215 °F |

| Pressure Sealing Capability | Up to 5 psi (when properly sealed) |

| Mounting | ½-inch sight pipe via integral collar |

| Lead / Cable Length | Typically ~8 ft |

| Visual Indicator | LED status indicator (24 V) |

| Parallel Wiring | Supports up to two sensors in parallel for expanded flame coverage |

| Housing & Construction | Rugged encapsulated sensor with protection for combustion environments |

Features & Benefits

Compact and rugged “Minipeeper” form factor allows installation in constrained spaces

LED indicator provides visual feedback of flame status

Parallel wiring capability supports enhanced flame path coverage

Sealed design for up to 5 psi when installed correctly

Reliable UV detection with honeywell-grade construction

Standard ½-inch collar simplifies mounting to sight tube

Applications

Boilers, furnaces, and burner systems requiring UV flame sensing

Installations with limited clearance or space constraints

Retrofits where visibility or flame path is challenging

Control systems needing LED flame status feedback

Installation & Maintenance Notes

Mount sensor properly with clear sight path to the flame

Use appropriate black iron sight tubing to avoid reflection interference

Avoid running sensor leads in the same conduit as ignition wiring

Periodically inspect and clean the sensor window

Replace the sensor if UV response weakens or if LED status becomes erratic

| Weight | 2 lbs |

|---|---|

| Dimensions | 6 × 4 × 4 in |

Be the first to review “C7027A1064 Honeywell Minipeeper UV Flame Sensor” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.